Antoine LeCoultre, who later put the foundation stone of the manufacture Jaeger-LeCoultre, has already in young years been a restless inventor. His pioneering spirit created – next to numerous other patents – a Millionmeter in 1844 and the first rocking bar winding mechanism in 1847. With the Millionmeter it was possible to measure up to a micrometer. The rocking bar winding mechanism enabled to wind and adjust the watch without an extra key. His small Atelier was soon called “La Grande Maison – the great house”.

Antoine LeCoultre

Today the watches at Jaeger-LeCoultre have names like Master Grande Tradition Tourbillon Cylindriques or Reverso TributeGyrotourbillon, the results of an incredible knowledge enabling the Maison to produce the most complicated watches. In 2016 Jaeger-LeCoultre opened a unique Atelier within the manufacture from which true pieces of art arise.

Vallée de Joux – a valley high in the mountains

Already in the 16th century, the family LeCoultre played an important role in Vallée de Joux. Pierre LeCoultre bought his first piece of land after taking refuge from the Huguenot war in France. He built houses, cultivated the land and raised livestock. Ten generations later Antoine LeCoultre decided that his Atelier (founded in 1833) must remain in his family and ancestors hometown. However the challenge was, that the Vallée de Joux is a valley at a height of 1000 meters, far away from any trade routes and surrounded by mountain passes, which are sometimes impassable during the winter months. It’s known to have the hardest climate in the Jura. But this couldn’t stop him and his son Elie.

The Atelier was founded 1833 in Vallée de Joux

In 1866 the small Atelier became the first manufacture in Vallée de Joux. In 1866 already, the manufacture employed 500 watchmakers, technicians and artisans. An incredible number for that time bearing in mind, that a business with 500 employees even in todays industrialized period is a remarkable achievement.

The Jaeger-LeCoultre manufacture today

The transformation from Lecoultre to Jaeger-Lecoultre

In 1903 the Parisian navy-watchmaker Edmond Jaeger looked for a Swiss manufacture that was able to produce his extra-thin movements. Jacques-David LeCoultre, the grandchild of the founder already produced perpetual calendars, chronographs and minute repeater in the 1890s. He accepted the challenge and created a collection with extremely thin watches. Amongst them the thinnest watch in the world, the 1,38 millimeters flat LeCoultre calibre 145. From now on the two watchmakers joined forces and established Jaeger-LeCoultre. Soon they started to develop their first wristwatches.

In the past 185 years Jaeger-LeCoultre developed approximately 1200 different movements and registered 400 patents. The Duoplan, Atmos and Reverso surely are some milestones from these creations. In 1929 the calibre 101 from the Duoplan-family became the smallest mechanical movement in the world. The trick: the movement was made in two levels in order to place a bigger balance for more precision. In 1928 the inventor Jean-Léon Reutter introduced his first prototype of the table watch Atmos of which Jaeger-LeCoutre made a Haute Horlogerie table watch. The Atmos still fascinates today as it’s almost a ‘Perpetuum Mobile’. It takes its energy from smallest changes in temperature – one degree Celsius leads to a power reserve of two days.

Jaeger-LeCoultre Atmos

Also the Reverso, which was launched in 1931 is still an iconic watch today. The idea was born after a business trip to India where Polo players wished to have a watch that they can wear during the game without getting damaged. The result was the Reverso, the Latin word for “I turn”.

Iconic – the Reverso Tribute Calendar

The ,Atelier des Métiers Rares’ – Searching for the roots of Antoine Lecoultre

The Jaeger-LeCoultre manufacture is still today placed in the small village of Le Sentier in the Vallée de Joux. However it is today a large architectural ensemble and centre of Haute Horlogerie and counts around 1000 employees. In 2016 Jaeger-LeCoultre opened a small Atelier called ‘Atelier des Métiers Rares’ within the manufacture, which is solely dedicated to the rare techniques of finishing: the enamelling, the engraving, the setting and the guilloching.

The ‘Atelier des Métiers Rares’ is dedicated to rare techniques of finishing

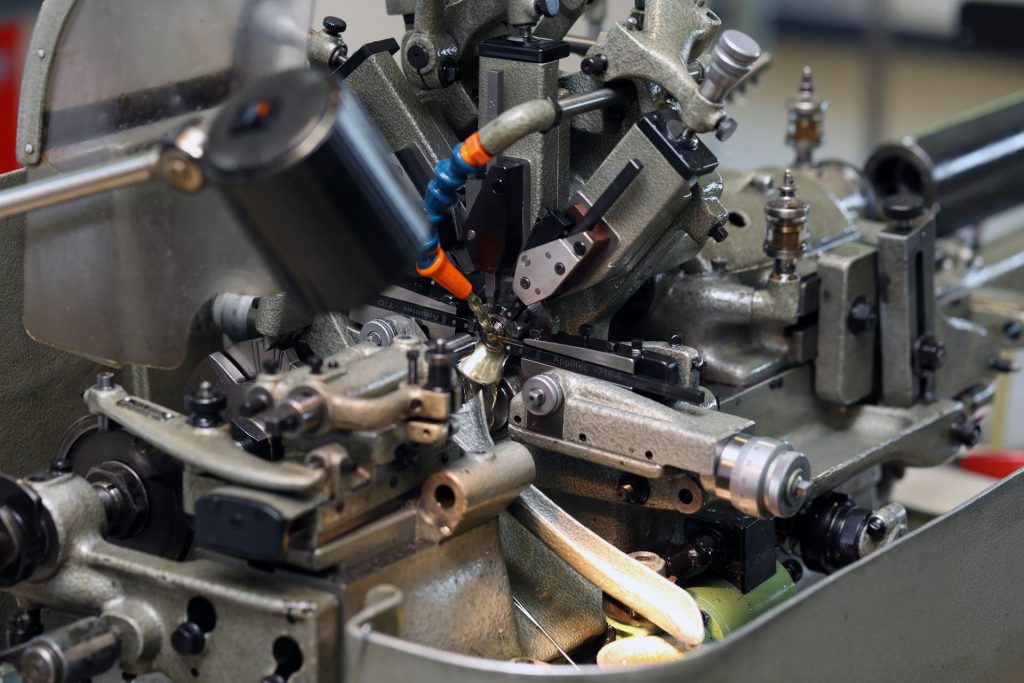

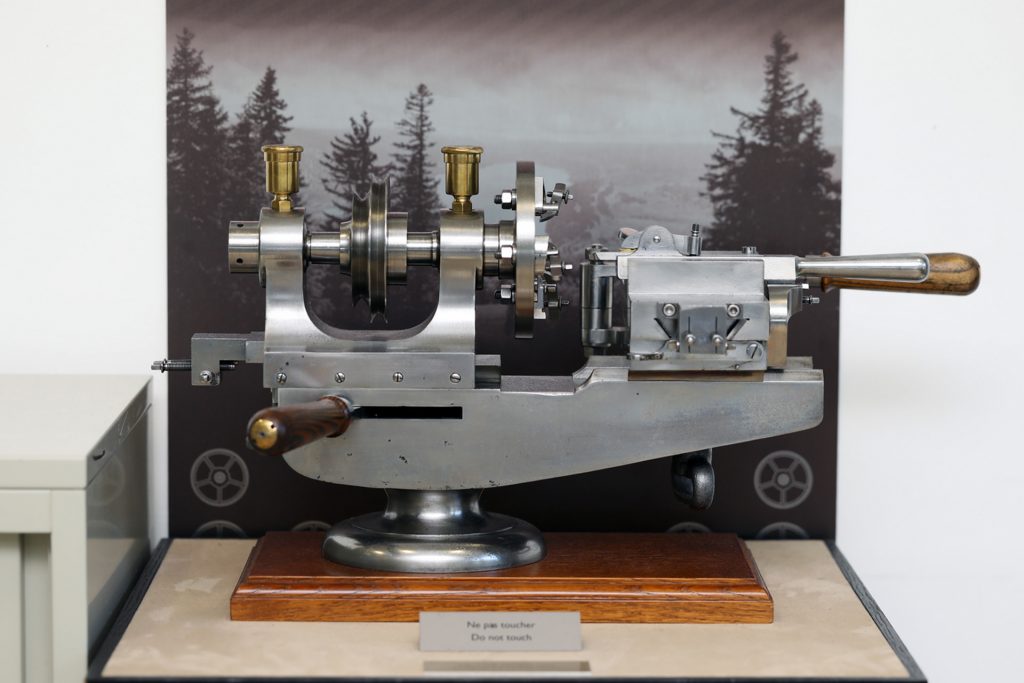

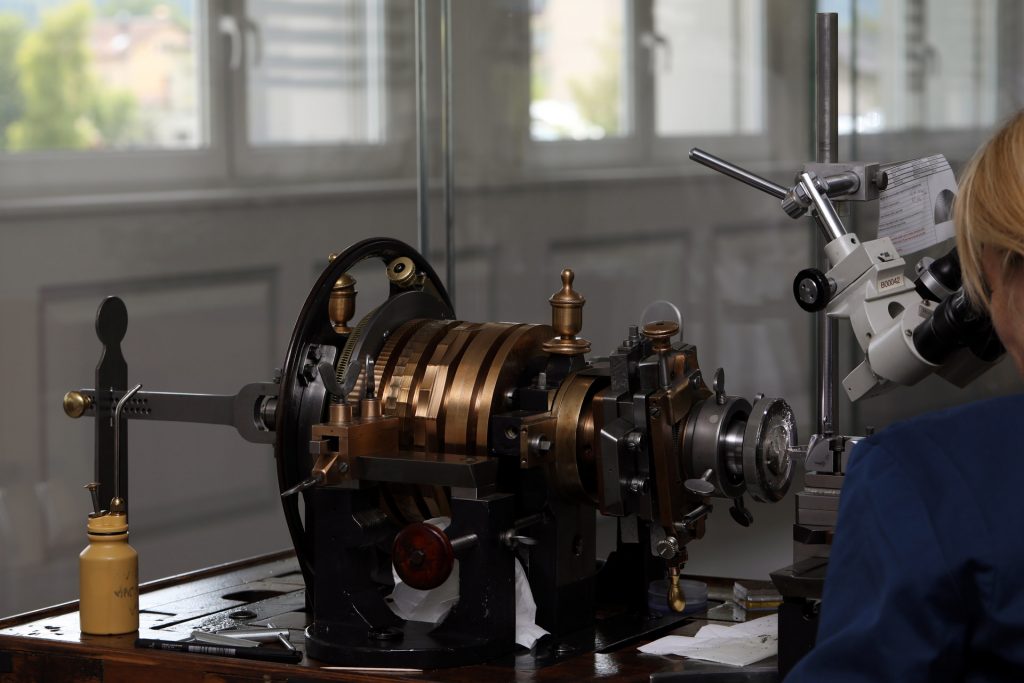

Recently we were kindly invited into the holy halls of the manufacture. It was impressive to see the approximately 30 artisans sitting in a separate room working meticulously and highly concentrated. The individual working tables are only separated by a pane. It enables the different departments to interact with each other and to follow each step. For example, if one component has been cut out incorrect, it might not leave enough space for the engravings. We also spotted three restored rose engines and a pantograph engraving machine from the early 20th century.

A restored rose engine from the early 20th century

An impressive wooden table stands in the middle of the Atelier. A hidden projector, which is connected to different cameras pointing at various working tables projects one of the work-steps onto the tabletop, in real time and increased by the fortyfold. A nice tool, especially for visitors who usually only see the Atelier through the window. Everything that happens in here requires plenty of concentration and complete peace – a gust of wind could have serious consequences.

Diamonds are placed onto the bezel

Haute Horlogerie

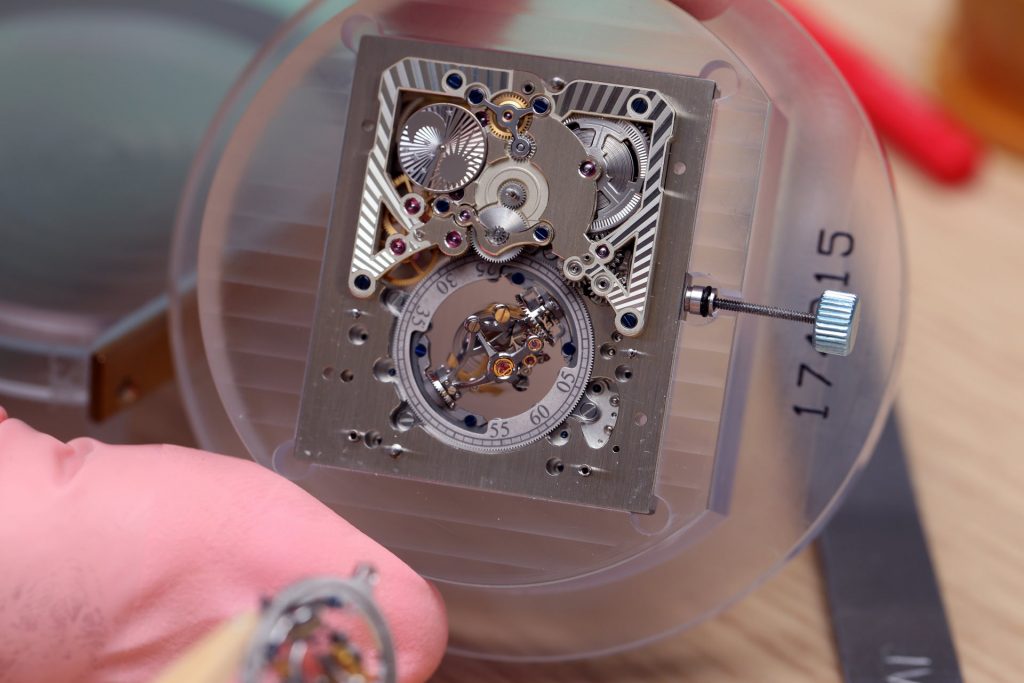

One of the first pieces of art that has evolved from the new ‘Atelier des Métiers Rares’ is the Reverso Tribute Gyrotourbillon 2 that was launched for the 85th birthday of the Reverso. As the name tells, it’s technically all about a Gyrotourbillon 2 (today there are 4 different types). What’s so special about the Gyrotourbillon, that it rotates spherical instead of 2-dimensional. The Gyrotourbillon 2 is made of around 100 components and demands one week of assembling from the watchmakers. It takes around a month for the whole watch.

Jaeger-LeCoultre Reverso Tribute Gyrotourbillon 2

The true skills from the ‘Atelier des Métiers Rares’ become visible on the backside of the watch. The movement is entirely skeletonized and the bridges decorated by hand, which is a great challenge taking into account the tiny proportions of the movement. The traditional watchmaking craftsmanship also becomes visible on the front of the watch, with the round dial and white grained “dauphine” hands in blued stainless steel.

Jaeger-LeCoultre Reverso Tribute Gyrotourbillon 2

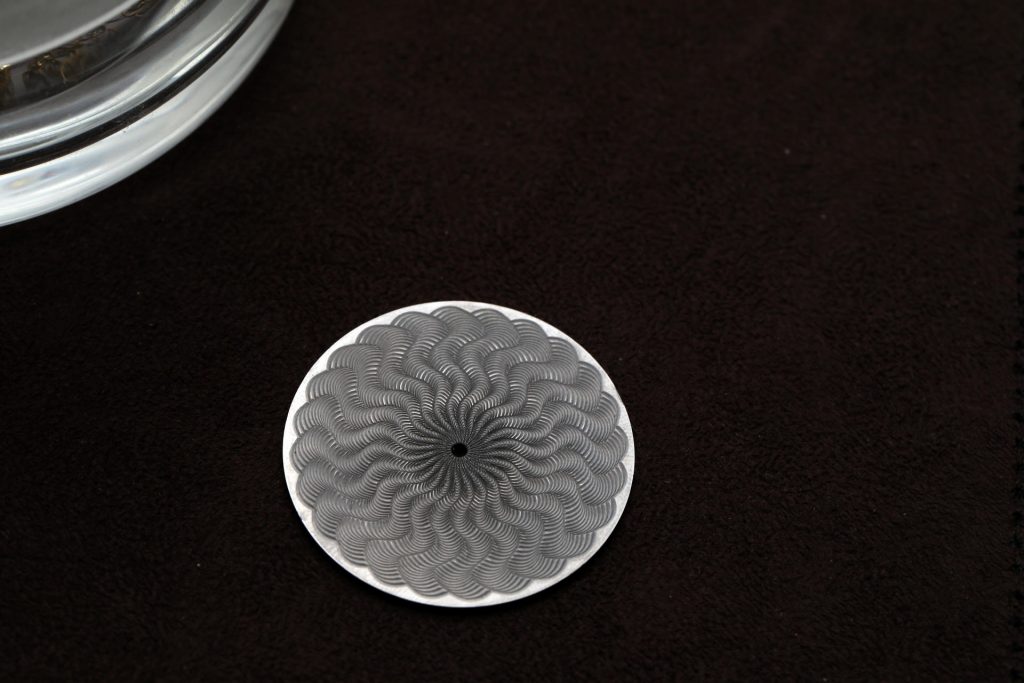

The lower part of the front is finished with a sun guilloche, matching the same finishing of the support plate, which appears by turning the case. A small round area has cleverly been spared out to also show the playful action of the Gyrotourbillon through the reflection from behind.

Jaeger-LeCoultre Reverso Tribute Gyrotourbillon 2

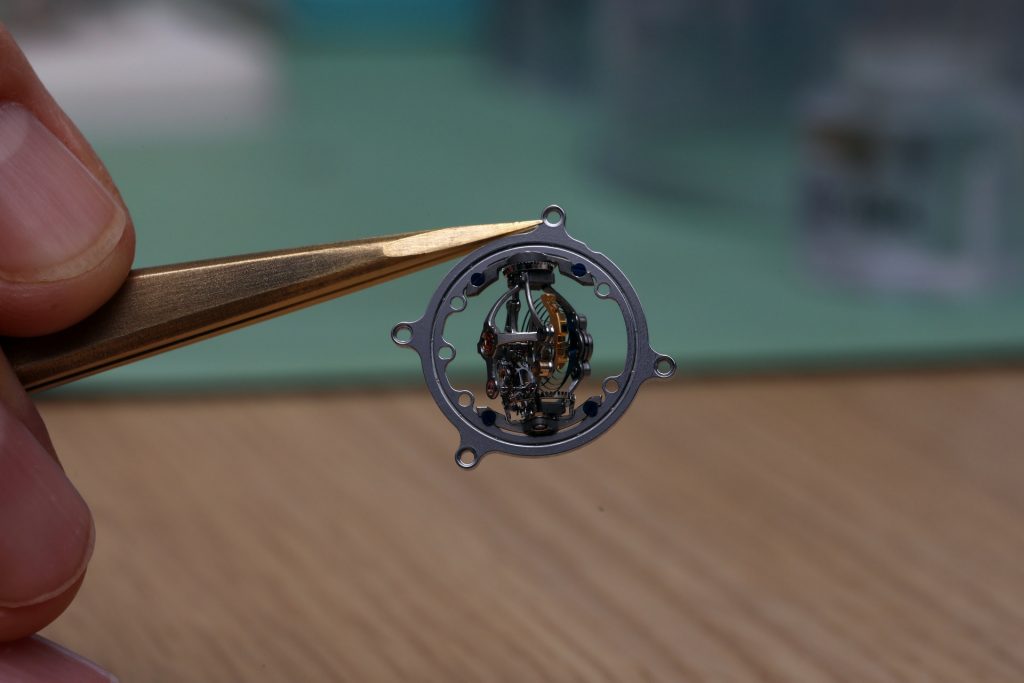

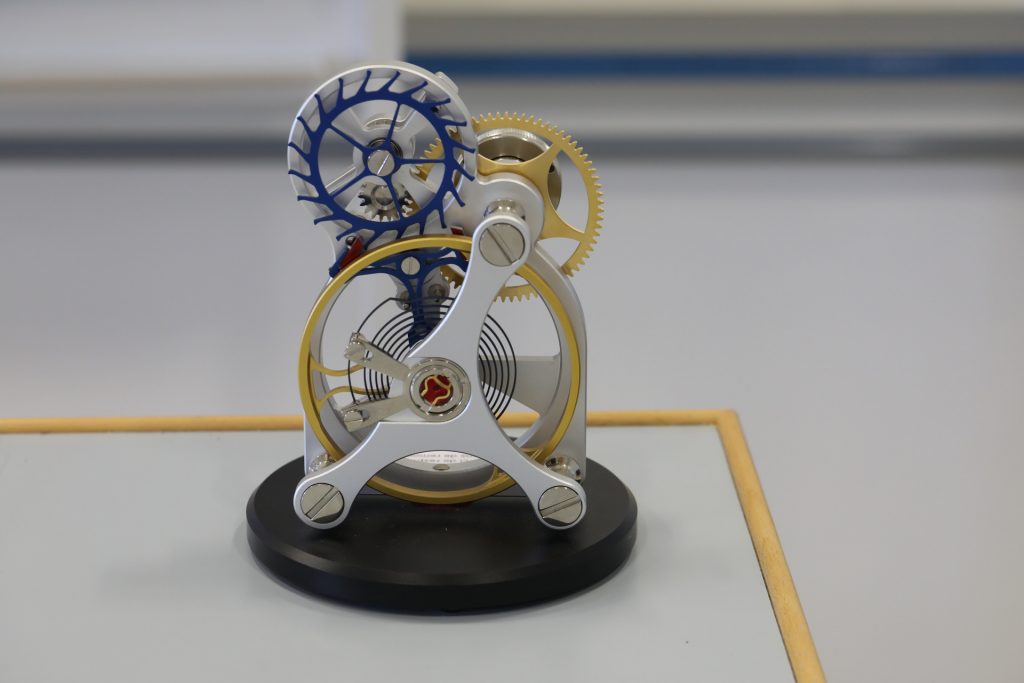

The Gyrotourbillon 3 (from the Master Grande Tradition Gyrotourbillon 3 Jubilee) is even more astonishing. Due to the lacking of the upper bridge you get an unhindered view on the tourbillon that seems to float. Compared to the cylindrical spring as used in the Gyrotourbillon 2, they now developed a spherical balance spring that has two terminal curves and improves the chronometrical power. It is hard to believe that this ensemble of approximately 100 components weights less then one gram.

Jaeger-LeCoultre Master Grande Tradition Gyrotourbillon 3 Jubilee

Certainly, Jaeger-LeCoultre was already able to master the requirements of Haute Horlogerie before the time of the ‘Atelier des Métiers Rares’. The calibre 383 of the Duomètre Unique Travel Time (launched in 2014) is characterized by a very beautiful finishing. Bridges and gear trains are hand-chamfered and feature polished sinks. Also the moving parts are hand-chamfered or adorned with polished sinks, or graced with a snailed or smoothed finish. The city names of the world’s 24 time zones are engraved on the back.

Jaeger-LeCoultre Duomètre Unique Travel Time

In 2014 Jaeger-LeCoultre presented the Master Grande Tradition Tourbillon Cylindrique à Quantième Perpétuel with a flying tourbillon and a new cylindrical balance spring that moves concentric and hence offers more precision. The tourbillon cage is made from Titanium Grade 5 and the balance is made of 14-carat gold. In addition to the flying tourbillon, the watch also offers a perpetual calendar that is set until the year 2100. The 22-carat gold oscillating weight bears a recognition of the gold metal that Jaeger-LeCoultre won at the 1889 Paris Universal Exposition in recognition of its horological expertise and its spirit of invention. The grained dial finish is silver plated.

Jaeger-LeCoultre Master Grande Tradition Tourbillon Cylindrique à Quantième Perpétuel

In 2015, Jaeger-LeCoultre introduced a tourbillon within their Master Grande Tradition Grande Complication that rotates anti-clockwise around the dial. However the tourbillon doesn’t show the time of the day as usual, but the time unit used by astronomers to keep track of the direction of the stars – the so-called Sidereal time. The former is measured with the sun as reference, the latter uses other, more distant fixed stars. A Sidereal day is almost four minutes shorter then a Solar day. A white mark shows the Sidereal time. The dial shows the image of the sky map of the northern hemisphere with the Great Bear, the Polaris and the belt of the twelve constellations that form the zodiac.

Jaeger-LeCoultre Master Grande Tradition Grande Complication

The complexity of the universe meets the complexity of Haute Horlogerie. For the minute repeater Jaeger-LeCoultre has developed a ‘crystal gong’ for a more intense acoustic.

Jaeger-LeCoultre Master Grande Tradition Grande Complication

Hardly any other manufacture is able to offer such a variety of Haute Horlogerie in their watches and at the same time focus so much on the finishing craft. During our visit in the ‘Atelier des Métiers Rares’ we positively noticed that the watchmakers and artisans work very closely and transparent with their trainees. The ‘Atelier des Métiers Rares’ also has the aim to ensure that the knowledge is passed on to the next generations.